MAXIFLO SHOULDERED LITE PIPE ™

A.C. Whalan & Co Pty Ltd have the exclusive distribution rights to this revolutionary FRAS Composite piping product. Developed under license with the CSIRO using aerospace technology the Maxiflo Shouldered Lite pipe™ offers a winning combination by incorporating the existing Shouldered jointing system whilst combating corrosion & weight issues. Having DPI approval & certification under MDG3006 MTR8 the pipe is fit for purpose and use in underground applications.

At half the weight of conventional steel pipe the Maxiflo Shouldered Lite Pipe ™ offers both OH&S and installation advantages. The weight saving will contribute to a lower overall installation cost and improved environmental impact. Pipe trailers can be constructed to carry lighter loads whilst providing the same lineal meterage of pipe. The lighter weight will also enable the pipe to be installed with a lower risk of injury. Originally designed for Underground coal mining Air & Water reticulation, the product is also extremely suitable as a Stand Pipe in methane drainage and corrosive tunneling applications.

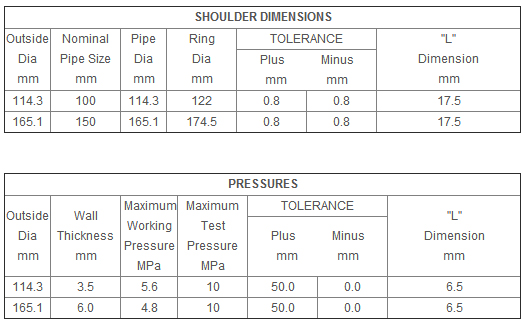

MAXIFLO SHOULDERED LITE PIPE ™ Recommended Working Pressure 3000 KPa Maximum Working Pressure 4800 KPa Maximum Test Pressure 10000 KPa DIMENSIONS - TOLERANCES - PRESSURES The Composite shouldered End provides an interference retaining fit for the Shouldered coupling system. The pipe ends are manufactured to the same dimensional spec's of the steel shouldered pipe system. The tolerances detailed under Shouldered Dimensions, please refer to the below table. The pipe ends should be measured with circumferential tape/vernier (or other effective averaging device) to obtain these figures.

- The above test and working pressures only relate to internal pressures in straight pipe when the maximum working temperature is 50 degrees Celsius.

- The design pressure of a piping system is limited to the working pressure of the jointing system. In the Shouldered Pipe Product the Shouldered couplings working pressure.